In 2024, my hometown planned to build a commercial housing project for our village. According to the proposal, every villager could receive 20 square meters, worth about 200,000 RMB.

But after more than 10 rounds of discussion, the proposal failed.

Why? Because using traditional construction methods, the average cost of such housing reached about 6,000 RMB per square meter—and that was only for bare shell houses. In today’s downturn economy, no one was willing to contribute more funding. Eventually, the plan was cancelled.

That also meant I lost my 200,000 RMB worth of housing.

I couldn’t help but compare this with the neighboring village. They had carried out a similar plan 10 years earlier, when the cost was only 4,000 RMB per square meter. At that time, labor costs were lower, and the project was affordable.

But a decade later, labor and material costs have risen. Sticking to the same old construction methods only leads to higher expenses. In a weak economy, few people can bear such costs.

A New Way of Thinking: Modular Homes

This made me wonder: Is there a way to save costs while still building quality housing?

That’s when I first came across modular prefabricated housing—made from wood, steel, or concrete modules. Unlike traditional construction, modular homes save both time and money.

I visited several examples:

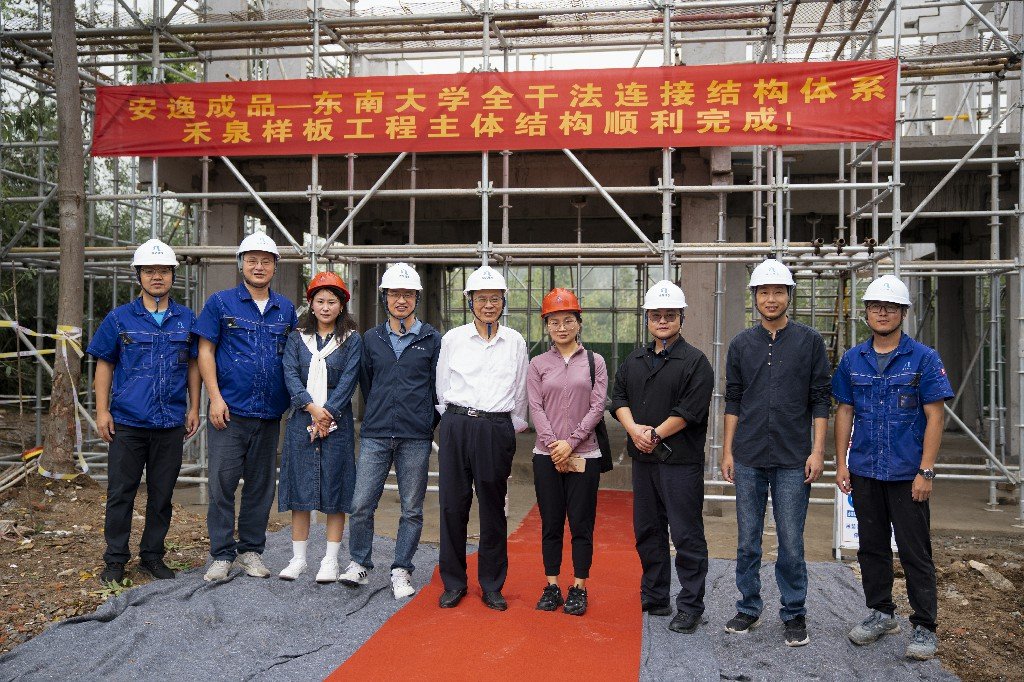

- A two-story concrete modular villa built in just 5 days by 3 workers for the main structure.

The interior finishing took about one month, and with cleaning included, the entire villa was completed in just a month and a half—from zero to fully built.

Even more surprising, I saw 27-floor commercial buildings constructed with the same technology.

My aunt also built a house. She originally wanted a single-story villa using traditional methods. But by choosing concrete modular housing, she spent only half the money—yet ended up with a two-story villa.

The result shocked me. The quality, speed, and cost-effectiveness were beyond imagination.

From then on, I started to deeply explore this industry. I found that concrete modular housing already has many successful projects both in China and abroad. In countries like Australia,Singapore,USA,UK & Germany and China, it has become a mature and trusted solution.

- Singapore: Since 2014, the government has made PPVC (Prefabricated Prefinished Volumetric Construction ) mandatory in many projects. They even built the world’s tallest modular concrete towers, the Clement Canopy (40 floors), showing how far the technology can go.

- China: With rapid urbanization and strong policy support, modular systems like C-MiC are widely used in affordable housing, urban renewal, and industrialized projects. Cities such as Shenzhen and Shanghai already have completed high-rise modular concrete residential buildings.

- Australia: Using systems like HBS, Australia has built projects such as the La Trobe Tower and Atira student housing, proving the technology works for both commercial and residential buildings. Modular projects there are often 30% faster than traditional methods.

- UK & Germany: In the UK, the government encourages off-site construction, and modular concrete systems are widely applied in apartments and housing. Germany integrates prefabricated concrete into multi-story housing and healthcare projects, with strong focus on industrial upgrading.

- USA: The U.S. has a complete industry chain, with companies like Coreslab Structures promoting modular solutions for schools, parking facilities, apartments, and residential projects. Its technology and market scale are globally leading.

All these cases show one thing: concrete modular housing is a proven, global trend, supported by policies, industry standards, and real projects.

What began as a personal regret—the cancelled housing plan in my hometown—has now turned into an opportunity. I realized that modular prefabricated housing isn’t just about saving money; it’s about changing how we build, making construction faster, more efficient, and more accessible in a world where costs keep rising.

Well-Known Concrete Modular Housing Projects in China

| Project Name | Location | Scale / Features | Highlights |

|---|---|---|---|

| Zhangkengjing Affordable Housing (“Huazhang Xinzhu”) | Longhua District, Shenzhen | 5 towers, about 99.7 m tall, totaling 2,740 affordable housing units, with a floor area of 173,000 m². | Built with 6,028 MiC modules. Most works (structure, MEP, interior) were completed in the factory. Structure was topped out in just 50 weeks, and the entire project was delivered within a year. |

| Meilin Road No.6 Affordable Housing / Anju Jingxinyuan | Futian District, Shenzhen | 30-story high-rise, providing around 696 rental housing units, total floor area ~44,500 m². | From the first module installation to a fully topped-out 30-story building took only 148 days. This was considered a “C-MiC 2.0” project, with innovations like micro-utility corridors, standardized modules, and digital design integration. |

The Huazhang Xinzhu talent housing project in Zhangkengjing Community—China’s first modular high-rise concrete building—which reduced solid waste by 75% during construction, setting a new benchmark for eco-friendly building practices.

SY Prefab Home – Concrete Modular Manufacturer in China

We are SY Prefab Home, a concrete modular home manufacturer based in China. Our company specializes in the design, production, and installation of modular concrete housing solutions, including:

- Residential Projects – villas, apartments, affordable housing

- Commercial Buildings – offices, hotels, student housing

- High-Rise Modular Structures – proven solutions up to 30+ floors

With a dedicated factory and skilled team, we deliver cost-effective, durable, and fast-build housing systems. A two-story modular villa can be assembled in just 5 days for the structure and completed in 1–2 months with interiors—cutting construction time dramatically compared to traditional methods.

Our solutions are widely applied in China and international markets, trusted for:

- Faster construction speed (30–50% time saving)

- Lower overall cost

- Consistent quality with factory production

- Strong, safe, and sustainable concrete structures

At SY Prefab Home, we aim to help developers, contractors, and distributors worldwide bring modern housing solutions to life—smarter, faster, and more affordable.

📩 Contact us to discuss wholesale, bulk projects, or partnership opportunities.