Prefabricated concrete housing is becoming one of the fastest-growing construction methods worldwide. Faster delivery, consistent quality, and safer sites make it ideal for developers, contractors, and government projects.

This blog takes you inside a real project built by SuYuan Home, showing how modular concrete structures come together step by step.

1. Project Kickoff Meeting: Setting the Foundation for Success

The visit started with a formal briefing with engineers, supervisors, and project partners. Large digital screens displayed project goals, timelines, and safety standards.

Everyone aligned on the core mission: deliver a high-quality prefabricated building efficiently and safely.

Why this matters for clients:

- Clear planning reduces delays

- Better coordination among all teams

- Early reviews prevent costly rework

suyuan home prefabricated concrete homes (4) 2. Technical Review & Quality Documents

Participants examined detailed construction drawings, material standards, and inspection checklists.

The technical presentation explained the structural system, stress calculations, and installation sequence for each prefab component.

This ensures:

- Accuracy of every panel, slab, and beam

- Consistent production quality

- Compliance with engineering and safety codes

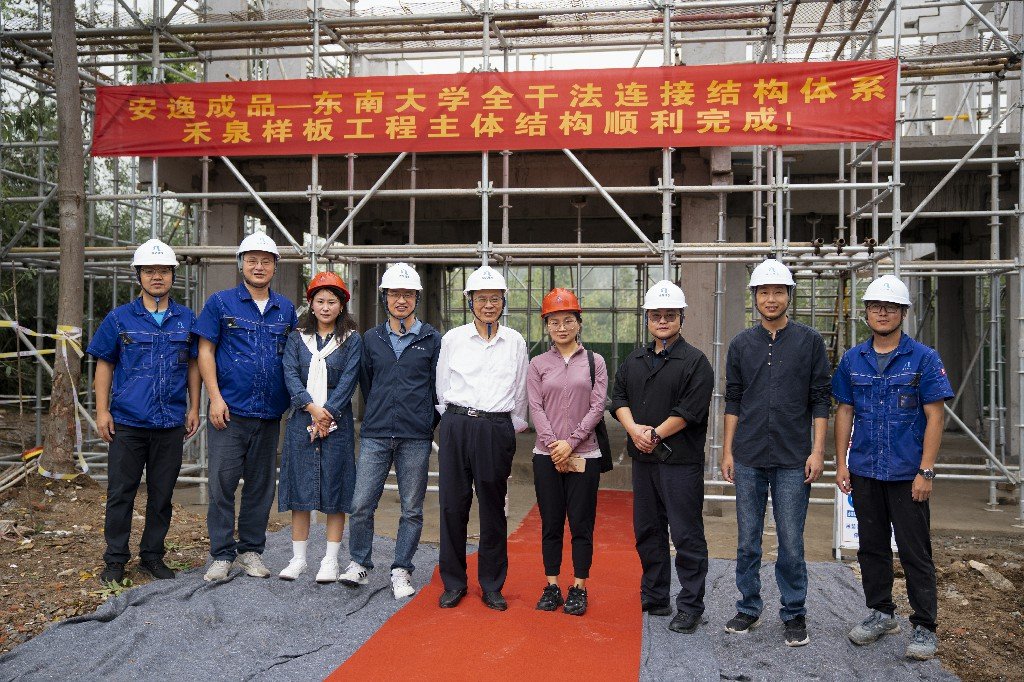

3. On-Site Walkthrough: Exploring the Modular Structure

The team then entered the building site to inspect the structural frame.

With helmets on, everyone observed the prefabricated beams, columns, floor slabs, and stair structures up close.

On-site highlights:

- Large floor-to-ceiling openings for natural light

- Smooth concrete finishes

- Completed prefabricated slabs

- Accurate alignment of load-bearing elements

Prefab offers one major advantage:

Precision happens in the factory, reducing on-site risks and mistakes.

4. Exterior Assembly: Scaffolding and Modular Installation

The photos show multiple sides of the building wrapped in scaffolding as each concrete module is installed.

Cranes lift panels and slabs into place, allowing the structure to rise quickly and steadily.

Benefits of SuYuan Home modular assembly:

- Faster installation

- Less construction waste

- Lower noise and dust

- Minimal weather impact

5. Interior Structure: Ready for Finishing Work

Inside the building, sunlight shines across the open floor plans.

The slab system, beams, and openings for utilities are already pre-formed during production.

Clients will appreciate:

- Smooth wall and slab surfaces

- Pre-planned electrical & plumbing routes

- Strong steel-concrete connections

- Reduced interior finishing time

6. Safety & Material Checks

Close-up images show anti-slip plates on walking paths and reinforcement details.

These inspections ensure every part of the structure meets SuYuan Home’s standards.

On-site checks include:

- Safety walkways

- Structural connection tests

- Concrete quality consistency

7. Why More Developers Choose SuYuan Home Prefabricated Concrete Houses

Faster Delivery

Factory production shortens overall build time.

Better Quality Control

Stable molds and controlled curing environments produce consistent results.

Cost Efficiency

Shorter timelines reduce labor and financing cost.

Cleaner & Safer Jobsites

Less formwork, fewer workers, smoother workflows.

Sustainable Construction

Reduced waste and improved material efficiency.

8. Build with Confidence — Choose SuYuan Home for Your Next Prefab Project

This project perfectly shows how SuYuan Home delivers reliable, efficient, and modern prefabricated concrete buildings. From detailed planning to on-site installation, every step reflects our focus on speed, quality, and long-term durability.

If you’re looking for a smarter and faster way to build—whether it’s housing, commercial spaces, schools, or public facilities—SuYuan Home is ready to support your project with proven modular construction expertise.

Ready to start your prefabricated housing project?

Contact SuYuan Home today and let’s build your next development with confidence.